Manufacturing Process

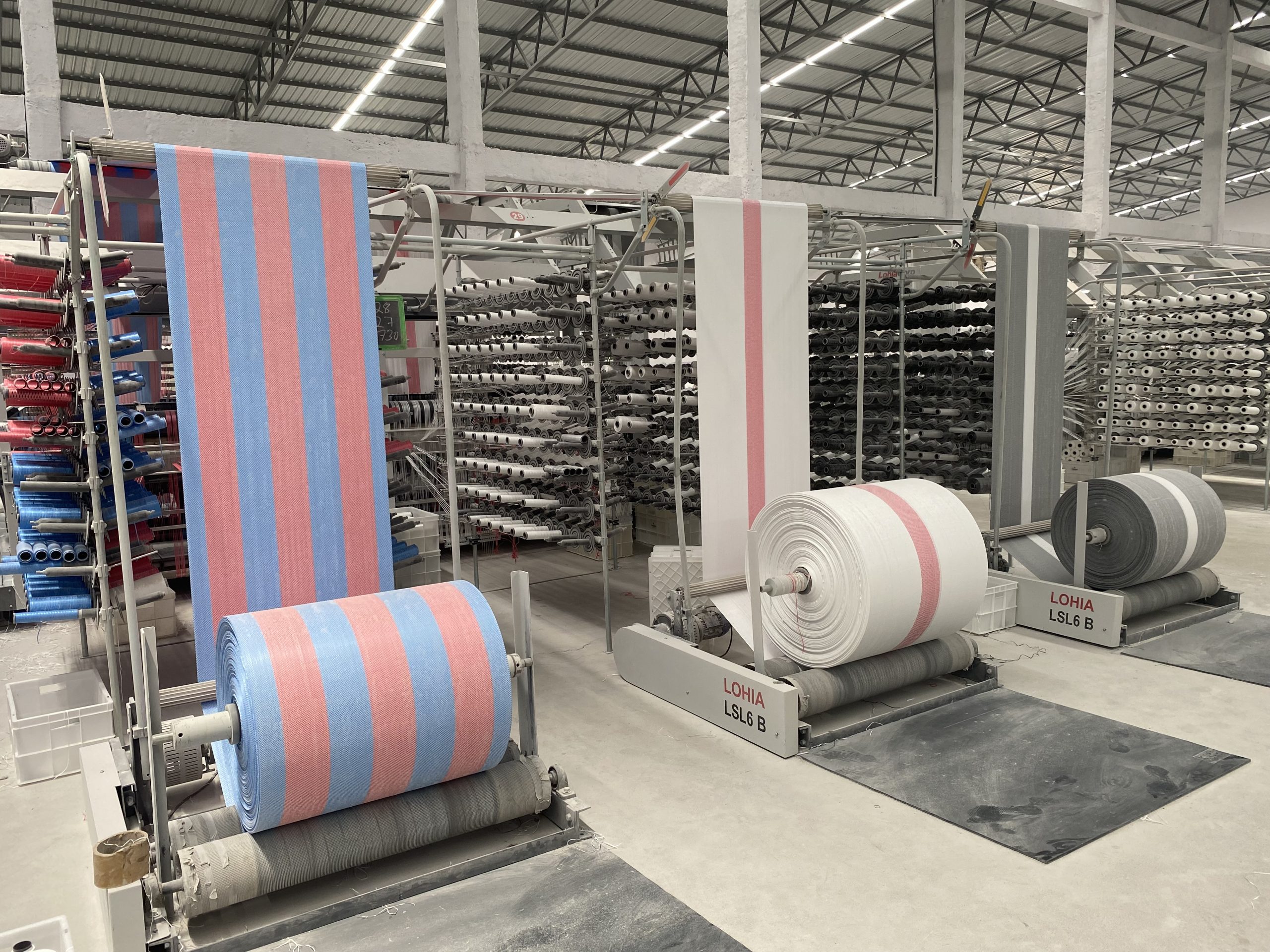

The manufacturing of woven bags involves various important steps. It begins with converting the raw materials into tapes

which ultimately aids in reaching the final product. Once the process of conversion is completed, and tapes are made, they

are weaved in the machine to convert them into woven fabric. Then, as per customer requirement, the extrusion coating process

takes place, or at times it is directly transferred to the finishing stage. At this stage, several procedures like flexo printing,

cutting, stitching and packing are being performed.

Material Combination

Woven bags are made using different materials such as the fabric, threads, crip tape, handle, pull tape and back seam glue.

All these materials with certain proportions aid the manufacturing of coated and uncoated woven bags.

Flexography Printing

Here at Knack, we also offer high-quality flexo printing at a very nominal rate. The best thing about this particular type of

printing is that it can be printed on uncoated bags as well. We can offer upto six different colours in flexo printing on woven

bags at very economical printing cost.